| A dynamometer is an apparatus that measures

mechanical force, speed, or power. In a typical engine/dynamometer test

cell, the end of the engine crank shaft is coupled to the dynamometer via

couplings and a drive shaft. When the engine is running, the dynamometer can

exert a braking force on the engine. Sensors on the dynamometer measure

engine speed and torque. Knowing these values, the dynamometer can calculate

engine-power output. Dynamometers allow us to reproduce a desired speed or

torque for a test under controlled conditions.

Motor and engine testing dynamometers apply

braking or drag resistance to motor rotation, and measure torque at various

speeds and power input levels. These devices measure the output torque of

motors, engines, gearboxes, transmissions, and other rotary machines.

|

Dynamometers use different methods to induce a braking force on the

device under test. Generally we can classify the Dynamometers into

four types:

What exactly are the benefits of different dynamometers? The

following chart describes the benefits of water brakes, Eddy Current,

AC, and DC dynamometers.

Hydraulic |

Eddy Current| DC

Dynamometer | AC

Dynamometer

|

Features

|

Water Brake

|

Eddy Current

|

DC

|

AC

|

|

Motoring ability |

No |

No |

Yes |

Yes |

|

Inertia |

Low |

Varies |

High |

Low |

|

Control stability |

Low |

Good |

Very

Good |

Excellent |

|

Speed

capability |

High |

High |

Moderate |

High |

|

Power

line regeneration |

No |

No |

Yes |

Yes |

|

Control response |

Slow |

Moderate |

Fast |

Fastest |

|

Cooling requirements |

High |

High |

Low |

Low |

|

Electrical requirements |

None |

Low |

High |

High |

|

Technology |

Old |

Old |

Old |

New |

|

Power

Range |

High |

High |

Moderate |

Moderate |

Friction Dynamometers

|

In a prony or friction brake

dynamometer the braking mechanism uses friction pads or brake shoes

to engage the rotating disk or drum coupled to the motor. Sometimes,

the dynamometer uses a rope or a belt that is wound around the

flywheel of the engine. One end of the belt is attached to a spring

balance whose other end is fixed to the ground. the other end of the

belt is attached to a load hanger that suspends freely. when the

load is to be changed load is added to the hanger or it is taken out

of it. The braking torque can then be calculated as the product of

the net force on the brake and the load arm. Brake power can then

easily be calculated by the formula:

b.p. = (2 π N T)/60 (in KW)

|

Prony brake

dynamometer |

Hydraulic Dynamometers

(Water

Brake Dynamometer)

|

In a hydraulic or water brake

dynamometer, braking drag is applied to the dynamometer rotor vanes

via water circulating between the rotor and the stator housing.

A hydraulic or a water brake is a

bladed rotor that churns water inside the dynamometer housing. The

more water inside, the greater the braking force exerted on the

device under test.

|

Advantages

|

Disadvantages

|

|

|

-

Difficult to control

-

High maintenance

|

|

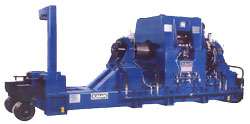

A hydraulic dynamometer

Taylor's

dynamometer water brake |

Visit SACMoney.Com for Money...

Success... Revenue!!!

Electrical

Dynamometers

a.

Eddy Current Dynamometer

An Eddy Current dynamometer produces braking torque using the

principle of eddy currents induced in a rotating metallic disk, immersed

in a magnetic field.

|

Advantages

|

Disadvantages

|

-

Low maintenance

-

Precise control

-

Widely accepted in the automotive industry

|

-

High inertia

-

More expensive

|

|

An

eddy current dynamometer |

b.

DC Dynamometer

|

A DC dynamometer is a DC motor that has been trunnion mounted. DC

dynamometers are essentially DC motors mounted and configured to provide

drag against the motor being tested and output the resultant torque and

power.

|

Advantages

|

Disadvantages

|

-

Motors and absorbs

-

Fast response

-

Air cooled (no water required)

-

Line regenerative

|

-

High cost (dynamometer and power amplifier)

-

High inertia

-

Requires high amperage electrical service

|

|

A DC dynamometer |

c.

AC Dynamometer

An AC dynamometer is similar to a DC dynamometer except it uses an AC

motor and is powered by alternating current. AC dynamometers are

essentially AC motors mounted and configured to provide drag against the

motor being tested and output the resultant torque and power.

|

Advantages

|

Disadvantages

|

- Motors and absorbs

- Very low inertia

- Very fast response

- Line regenerative

|

- High cost

- Requires high amperage electrical service

|

|

An AC

dynamometer |

|

Electronic Dynamometers

|

Electronic dynamometers are essentially, the electrical

dynamometers, equipped with extensive electronics to measure different

parameters related with the engine quickly with a great precision. These

dynamometers are provided with electronic sensors and transducers that

measure forces and temperature of different parts of the engine and directly

give results in the form of electric pulses. Then these dynamometer

calculate different parameters using a self computer and display them on the

digital screen normally placed on user friendly display panels. Different

parameters like load, etc can be increased or decreased from the panel and

can be set accurately.

|

An

electronic Dynamometer console panel |

Visit SACMoney.Com for Money... Success... Revenue!!!

|

APPLICATIONS

Common applications for dynamometers include general

purpose, automotive, aircraft or aerospace, chain or belt drives, gearboxes,

fluid power systems, gas or diesel engines, industrial, marine,

transmissions, and turbines. All dynamometers will typically have speed and

power feedback for performance testing and monitoring. Typical features

include encoders or other speed / position sensors, torque arms, and

reaction sensors. Common dynamometer interfaces include integral control

console, separate console, computer, or modem or remote control. Features

common to dynamometers include PID control, flow control or throttling, data

acquisition or logging, alarms, motor power analysis, and engine exhaust

analysis.

<<Previous

Page

Next Page >> |

![]()